Road roller cylinder XCMG road roller izingxenye ezisele

Isilinda

Ngenxa yokuthi kunezinhlobo eziningi zezingxenye ezisele, asikwazi ukuziveza zonke kuwebhusayithi. Sicela uzizwe ukhululekile ukusithinta ukuze uthole ezithile

Inzuzo

1. Sikuhlinzeka ngemikhiqizo yoqobo neyemakethe yangemuva

2. Kusukela kumkhiqizi kuya ekhasimendeni ngokuqondile, ukonga izindleko zakho

3. Isitokwe esizinzile sezingxenye ezijwayelekile

4. Ngesikhathi Sokulethwa Kwesikhathi, esinezindleko zokuncintisana zokuthumela

5. Professional futhi ngesikhathi ngemva kwenkonzo

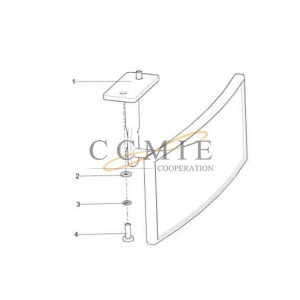

Ukupakisha

Amabhokisi e-Carton, noma ngokusho kwesicelo samakhasimende.

incazelo

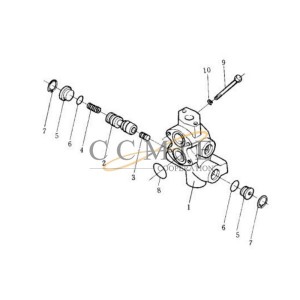

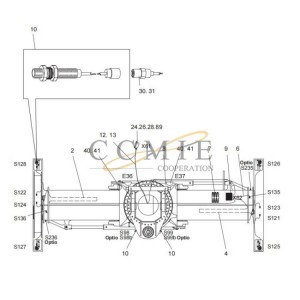

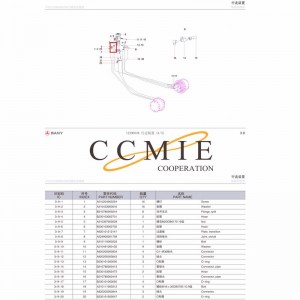

I-hydraulic cylinder ingahlukaniswa ibe yi-piston cylinder\plunger cylinder kanye ne-swing cylinder kusuka esakhiweni.

Amasilinda angahlukaniswa abe amasilinda e-piston \ amasilinda efilimu \ amasilinda akhishwayo avela esakhiweni.

Umgomo wokusebenza we-hydraulic cylinder uthi: uma kukhulunywa ngesimiso sayo sokusebenza, ngizoqala ngikhulume ngezingxenye zayo ezinhlanu eziyisisekelo, i-1-cylinder nekhanda le-cylinder 2-piston kanye ne-piston rod 3-seal device 4-buffer device 5- qeda Idivayisi

Umsebenzi wohlobo ngalunye lwesilinda ucishe ufane. Ngizothatha ujeke wezandla ukukhombisa umsebenzi wawo. Ijekhi empeleni iyisilinda elilula. Uwoyela we-hydraulic wenziwa nge-booster manual (hydraulic manual pump). Ngemuva kokuthi i-valve eyodwa ingene ku-cylinder, uwoyela we-hydraulic ongena ku-cylinder awukwazi ukuhlehliswa ngenxa ye-valve eyodwa, uphoqa induku yesilinda phezulu, bese umsebenzi uqhubeka nokwenza uwoyela we-hydraulic uqhubeke nokungena ku-cylinder ye-hydraulic, ngakho-ke. iyaqhubeka ikhuphuka, futhi izokwehla. Ngaleso sikhathi, vula i-valve ye-hydraulic ukuze ubuyisele uwoyela we-hydraulic ethangini. Lona umsebenzi olula, futhi eminye ithuthukiswa ngalesi sisekelo.

I-hydraulic cylinder iyisici esiphezulu esiguqula amandla asebenza ngaphansi kwamanzi abe amandla omshini ohlelweni lwe-hydraulic. Amaphutha angafingqwa ngokuyisisekelo njengokungasebenzi kahle kwe-hydraulic cylinder, ukungakwazi ukusunduza umthwalo, kanye nokushelela noma ukukhasa kwepiston. Akuvamile ukuthi imishini ime ngenxa yokwehluleka kwe-hydraulic cylinder. Ngakho-ke, ukunakwa kufanele kukhokhwe ekuxilongeni ukwehluleka kanye nokusetshenziswa nokugcinwa kwe-cylinder ye-hydraulic.

1. Ukuxilongwa kwephutha nokwelashwa

1. Ukungasebenzi kahle noma ukungasebenzi kahle

Izizathu nezindlela zokwelashwa zimi kanje:

(1) I-valve core ibambeke noma imbobo yevalvu ivimbekile. Uma i-valve yokugeleza noma i-spool ye-valve eqondisayo ibhajwe noma imbobo ye-valve ivimbekile, isilinda esisebenza ngaphansi kwamanzi sijwayele ukungasebenzi kahle noma ukungasebenzi kahle. Ngalesi sikhathi, hlola ukungcoliswa kwamafutha; hlola ukuthi ukungcola noma ama-colloidal deposits abambekile yini kumongo wevalvu noma avimbe imbobo yevalvu; hlola ukuguga komzimba we-valve, hlanza bese ubuyisela isihlungi sesistimu, hlanza ithangi likawoyela, bese ubuyisela i-hydraulic medium.

(2) I-piston rod kanye nesilinda kubambekile noma isilinda esisebenza ngehydraulic sivinjiwe. Ngalesi sikhathi, kungakhathaliseki ukuthi uyisebenzisa kanjani, isilinda esisebenza nge-hydraulic asinyakazi noma sinyakaze kancane. Ngalesi sikhathi, hlola ukuthi izigxivizo ze-piston ne-piston rod ziqine kakhulu, ukuthi ukungcola namadiphozithi e-colloidal kungenile yini: ukuthi ulayini we-axis we-piston rod kanye ne-cylinder barrel kuqondile, noma izingxenye ezigqokiwe nezigxivizo akuvumelekile, nokuthi ingabe umthwalo mkhulu kakhulu. Okukhulu.

(3) Ingcindezi yokulawula yesistimu ye-hydraulic iphansi kakhulu. Ukumelana ne-throttling epayipini lokulawula kungase kube kukhulu kakhulu, i-valve yokugeleza ilungiswa ngendlela engafanele, ukucindezela kokulawula akufanelekile, futhi umthombo wokucindezela uyaphazamiseka. Ngalesi sikhathi, hlola umthombo wengcindezi yokulawula ukuze uqinisekise ukuthi ingcindezi ilungiswa enanini elishiwo lesistimu.

(4) Umoya ungena ohlelweni lwe-hydraulic. Ikakhulukazi ngoba kukhona ukuvuza ohlelweni. Ngalesi sikhathi, hlola izinga loketshezi lwethangi likawoyela we-hydraulic, ama-seal kanye namajoyinti epayipi ohlangothini lokumunca lwephampu ye-hydraulic, kanye nokuthi isihlungi sokumunca uwoyela singcole kakhulu yini. Uma kunjalo, uwoyela we-hydraulic kufanele wengezwe, ama-seal kanye namapayipi ahlangene kufanele aphathwe, futhi isici sokuhlunga esimahhadla kufanele sihlanzwe noma sishintshwe.

(5) Ukunyakaza kokuqala kwe-hydraulic cylinder kuhamba kancane. Endabeni yokushisa okuphansi, uwoyela we-hydraulic une-viscosity ephezulu kanye ne-fluidity empofu, okwenza isilinda se-hydraulic sihambe kancane. Indlela yokuthuthukisa iwukuba esikhundleni sikawoyela we-hydraulic nge-viscosity engcono nokusebenza kwezinga lokushisa. Emazingeni okushisa aphansi, sebenzisa i-heater noma usebenzise umshini ukuwufudumeza ukwandisa izinga lokushisa likawoyela ekuqaleni. Izinga lokushisa elivamile likawoyela osebenzayo wesistimu kufanele ligcinwe cishe ku-40°C.

2. Umthwalo awukwazi ukushayelwa uma usebenza

Ukubonakaliswa okuyinhloko ukuma okungalungile kwe-piston rod, ukusunduza okunganele, isivinini esincishisiwe, umsebenzi ongazinzile, njll. Izizathu yilezi:

(1) Ukuvuza ngaphakathi kwe-hydraulic cylinder. Ukuvuza kwangaphakathi kwe-hydraulic cylinder kufaka phakathi ukuvuza okubangelwa isivalo somzimba we-hydraulic cylinder, uphawu lwe-piston rod kanye nesembozo sokuvala, kanye nokuguga ngokweqile kwe-piston seal.

Isizathu sokuvuza kophawu phakathi kwenduku yepiston kanye nesembozo sophawu ukuthi uphawu luyashwabana, luyakhama, ludabukile, lugugile, luyaguga, luwohlokile, lukhubazekile, njll. Ngalesi sikhathi, uphawu olusha kufanele lufakwe esikhundleni.

Isizathu esiyinhloko sokugqoka ngokweqile kwe-piston seal ukulungiswa okungalungile kwe-valve yokulawula isivinini, okuholela ekucindezelweni okudlulele emuva nokufakwa okungalungile kwesigxivizo noma ukungcoliswa kwamafutha we-hydraulic. Okwesibili ukuthi izinto zangaphandle zingena ngesikhathi sokuhlanganisa futhi izinga lempahla yokuvala alilungile. Umphumela uba ukunyakaza kancane nokuba buthakathaka. Ezimweni ezimbi kakhulu, kuzodala umonakalo ku-piston nesilinda, okubangela ukwenzeka "kwe-cylinder pulling". Indlela yokwelapha ukulungisa i-valve yokulawula isivinini, nokwenza imisebenzi edingekayo kanye nokuthuthukiswa ngokuvumelana nemiyalelo yokufaka.

(2) Ukuvuza komjikelezo we-hydraulic. Kubandakanya ukuvuza kwama-valve nemigqa ye-hydraulic. Indlela yokulungisa iwukuhlola nokuqeda ukuvuza kwepayipi loxhumano lwe-hydraulic ngokusebenzisa i-valve ehlehlayo.

(3) Uwoyela we-hydraulic udlulelwa emuva ethangini likawoyela ngevalvu yokuchichima. Uma ukungcola kungena ku-valve yokuchichima futhi kugxumeke i-spool, okwenza i-valve yokuchichima ivuleke ngokuvamile, uwoyela we-hydraulic uzoyidlula i-valve echichimayo futhi ageleze abuyele ethangini likawoyela, kubangele ukuthi kungabikho uwoyela ongena kusilinda esidonsa amanzi. Uma umthwalo umkhulu kakhulu, nakuba ingcindezi elawulayo ye-valve yokukhulula ifinyelele inani eliphakeme elilinganiselwe, isilinda esisebenza nge-hydraulic asikwazi ukuthola i-thrust edingekayo esenzweni esiqhubekayo futhi ayinyakazi. Uma ingcindezi yokulungiswa iphansi, amandla e-vertebral adingekayo ekulayisheni namanje awakwazi ukufezwa ngenxa yokucindezela okunganele, okubonakaliswa njengokungaphumeleli okwanele. Ngalesi sikhathi, hlola futhi ulungise i-valve yokuchichima.

3. I-piston iyashelela noma iyakhasa

Ukuslayida noma ukukhasa kwepistoni yesilinda esisebenza nge-hydraulic kuzokwenza isilinda esisebenza ngehydraulic sisebenze singazinzi. Izizathu eziyinhloko yilezi:

(1) Ingaphakathi le-hydraulic cylinder liyavilapha. Izingxenye zangaphakathi ze-hydraulic cylinder zihlanganiswe ngendlela engafanele, izingxenye zikhubazekile, zigugile, noma ukubekezelelana kwejometri kudlula umkhawulo, futhi ukumelana nesenzo kukhulu kakhulu, ukuze ijubane le-piston le-hydraulic cylinder lishintshe ngokuma kwe-stroke, futhi iyashelela noma ikhase. Isizathu sibangelwa ikakhulukazi ikhwalithi yokuhlangana empofu yezingxenye, izibazi ezingaphezulu noma amafayili ensimbi akhiqizwa yi-sintering, okwandisa ukumelana nokunciphisa isivinini. Isibonelo: i-piston ne-piston rod ayigxilile noma i-piston rod igobile, indawo yokufaka isilinda se-hydraulic noma i-piston rod kumzila wesitimela iyasuswa, indandatho yokuvala ifakwe ngokuqinile kakhulu noma ngokukhululekile, njll. Isixazululo ukulungisa noma ukulungisa, ukufaka esikhundleni sezingxenye ezilimele futhi kukhishwe amafayili ensimbi.

(2) Ukugcotshwa okungalungile noma ukwenziwa kahle kwe-bore diameter yesilinda esisebenza ngamanzi. Ngenxa yokuthi i-piston nesilinda, i-guide rail kanye ne-piston rod konke kunokunyakaza okuhlobene, uma ukugcotshwa kungalungile noma i-hydraulic cylinder bore impofu kakhulu, kuzokwandisa ukuguga futhi kunciphise ukuhambisana komugqa omaphakathi wesilinda. Ngale ndlela, lapho i-piston isebenza ku-hydraulic cylinder, ukumelana nokungqubuzana kuzoba kukhulu futhi kwesinye isikhathi kube kuncane, kubangele ukushelela noma ukukhasa. Indlela yokuqeda iwukugaya isilinda esisebenza nge-hydraulic kuqala, bese ulungisa ipiston ngokwezidingo ezifanayo, ugaye induku yepiston, bese ulungisa umkhono womhlahlandlela.

(3)Ipompo ye-hydraulic noma i-hydraulic cylinder ingena emoyeni. Ukucindezelwa noma ukunwetshwa komoya kungabangela ukuthi ipiston ishelele noma ikhase. Izinyathelo zokuxazulula inkinga ukuhlola iphampu ye-hydraulic, ukusetha idivayisi yokukhipha umoya okhethekile, futhi usebenzise ngokushesha i-exhaust izikhathi eziningana phakathi nayo yonke i-stroke.

(4) Izinga lophawu lihlobene ngokuqondile nokushelela noma ukukhasa. Uma uphawu lwe-O-ring lusetshenziswa ngaphansi kwengcindezi ephansi, uma luqhathaniswa nophawu olumise okwe-U, ngenxa yokucindezela okuphezulu kwendawo kanye nomehluko omkhulu wokumelana nokungqubuzana okuguquguqukayo nokumile, kulula ukushelela noma ukukhasa; ukucindezela okungaphezulu kwesigxivizo esimise okwe-U kuyanda ngengcindezi Nokho, nakuba umphumela wokuvala uthuthukiswa ngendlela efanayo, umehluko phakathi kokumelana nokungqubuzana okuguquguqukayo nokuma kwe-static nawo uyakhula, futhi ukucindezela kwangaphakathi kuyanda, okuthinta ukunwebeka kwenjoloba. Ngenxa yokwanda kokumelana nokuthintana nodebe, indandatho yokuvala izotsheka futhi udebe luzonwebeka. Kulula futhi ukubangela ukushelela noma ukukhasa. Ukuyinqanda ukuthi ingagingqiki, indandatho yokuyisekela ingasetshenziswa ukuyigcina izinzile.

Indawo yethu yokugcina impahla1

Pakisha bese uthumela

- I-Aerial Boom Lift

- Iloli lokulahla i-China

- Cold Recycler

- I-Cone Crusher Liner

- I-Container Side Lifter

- Ingxenye ye-Dadi Bulldozer

- Okunamathiselwe kwi-Forklift Sweeper

- Izingxenye ze-Hbxg Bulldozer

- Izingxenye ze-Howo Engine

- I-Hyundai Excavator Hydraulic Pump

- Izingxenye ze-Komatsu Bulldozer

- I-Komatsu Excavator Gear Shaft

- I-Komatsu Pc300-7 Excavator Hydraulic Pump

- Izingxenye zeBulldozer ze-Liugong

- Sany Concrete Pump Spare Parts

- Izingxenye ezisele ze-Sany Excavator

- Izingxenye Zenjini ye-Shacman

- Shantui Bulldozer Clutch Shaft

- I-Shantui Bulldozer Ixhuma Iphinikhodi ye-Shaft

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

- I-Shantui Bulldozer Lifting Cylinder Repair Kit

- Izingxenye ze-Shantui Bulldozer

- Shantui Bulldozer Reel Shaft

- I-Shantui Bulldozer Reverse Gear Shaft

- Izingxenye ze-Shantui Bulldozer Spare

- Shantui Bulldozer Winch Drive Shaft

- I-Shantui Dozer Bolt

- I-Shantui Dozer Front Idler

- Ikhithi yokulungisa i-Shantui Dozer Tilt Cylinder

- I-Shantui Sd16 Bevel Gear

- I-Shantui Sd16 Brake Lining

- I-Shantui Sd16 Door Assembly

- I-Shantui Sd16 O-Ring

- I-Shantui Sd16 Track Roller

- I-Shantui Sd22 Bearing Sleeve

- I-Shantui Sd22 Friction Disc

- I-Shantui Sd32 Track Roller

- Izingxenye ze-Sinotruk Engine

- Iloli Lokudonsa

- Izingxenye ze-Xcmg Bulldozer

- Izingxenye ze-Xcmg Bulldozer Spare

- I-Xcmg Hydraulic Lock

- Ukudluliselwa kwe-Xcmg

- Izingxenye ze-Yuchai Engine