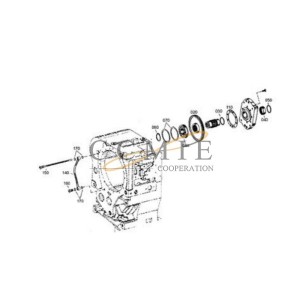

Izingxenye ezisele ze-Wheel loader rocker ze-XCMG Liugong wheel loader

i-rocker

Ngenxa yokuthi kunezinhlobo eziningi zezingxenye ezisele, asikwazi ukuziveza zonke kuwebhusayithi. Sicela uzizwe ukhululekile ukusithinta ukuze uthole ezithile.

inzuzo

1. Sikuhlinzeka ngemikhiqizo yoqobo neyemakethe yangemuva

2. Kusukela kumkhiqizi kuya ekhasimendeni ngokuqondile, ukonga izindleko zakho

3. Isitokwe esizinzile sezingxenye ezijwayelekile

4. Ngesikhathi Sokulethwa Kwesikhathi, esinezindleko zokuncintisana zokuthumela

5. Professional futhi ngesikhathi ngemva kwenkonzo

ukupakisha

Amabhokisi e-Carton, noma ngokusho kwesicelo samakhasimende.

incazelo

Umsebenzi we-tappet ukudlulisa ukusunduza kwekhamera ku-push rod noma i-valve rod, ukusunduza i-push rod noma i-valve ukuze unqobe amandla esiphethu se-valve, futhi ngesikhathi esifanayo ithwale amandla asemaceleni asetshenziswa i-camshaft lapho. iyazungeza. Indawo yokufaka imbobo yomhlahlandlela ebhodwe engxenyeni ehambisanayo yesilinda block noma ikhanda lesilinda, ngokuvamile elenziwe ngensimbi eyi-nickel-chromium alloy cast iron noma i-cold shock alloy cast iron.

1)Ompompi abavamile Kunezinhlobo ezintathu zamatapethi ajwayelekile: ompompi abamise okwesikhunta, ompompi abayisilinda kanye nohlobo lwamarola. I-fungus-shaped and cylindrical tappets inganciphisa isisindo sayo ngenxa yefomu elingenalutho; ama-roller-type tappets axhumene nomugqa ngenxa yefomu lokuxhumana, futhi ama-roller angakwazi ukugoqa ngokukhululekile, okunganciphisa ukuguga. Ompompi abavamile bayizakhiwo eziqinile futhi abakwazi ukuqeda ngokuzenzakalelayo ukuphuma kwe-valve. Ngakho-ke, izinjini ezisebenzisa ompompi abavamile kufanele zilungise imvume ye-valve.

2)Izici zompompi odonsa amanzi: Inzuzo enkulu yompompi bama-hydraulic ngaphezu kompompi abavamile ukuthi bangakwazi ukuqeda ukuphuma kwe-valve yenjini ngaphandle kokulungisa ukuphuma kwe-valve; ngesikhathi esifanayo, ompompi bama-hydraulic banganciphisa futhi umsindo wokudlulisa we-valve yenjini.

3)Isakhiwo se-tappet ye-hydraulic: umzimba we-tappet ushiselwe emzimbeni owodwa ngesembozo esingaphezulu nesilinda, futhi ungakwazi ukuhamba phezulu naphansi emgodini we-tappet wekhanda lesilinda. Imbobo yangaphakathi kanye nendilinga yangaphandle yomkhono kokubili sekuphelile futhi kuphansi. Isiyingi esingaphandle sihambisana nembobo yomhlahlandlela ku-tappet, futhi imbobo yangaphakathi ifanelana ne-plunger. Zombili zinganyakaza zihlobene. Isiphethu esinxephezelayo sifakwa ngaphansi kwesilinda esisebenza ngamanzi ukuze ucindezele i-valve yebhola endaweni ye-valve ye-plunger. Ingakwazi futhi ukugcina indawo engaphezulu ye-tappet isondelene nendawo yekhamera ukuze kuqedwe ukuphuma kwe-valve. Lapho i-valve yebhola ivala imbobo ephakathi ye-plunger, i-tappet ingahlukaniswa ngamakamelo amabili kawoyela, igumbi likawoyela eliphansi eliphansi kanye negumbi eliphansi lamafutha okucindezela okuphezulu; ngemuva kokuvulwa kwe-valve yebhola, kwakhiwa igumbi.

4) Isimiso sokusebenza se-tappet ye-hydraulic Lapho i-groove yamafutha e-annular emzimbeni we-tappet ihambisana nembobo yamafutha e-oblique ekhanda lesilinda, uwoyela osohlelweni lokugcotshwa kwenjini ugelezela emgodini kawoyela onengcindezi ephansi ngokusebenzisa imbobo yamafutha e-oblique kanye ne-annular. uwoyela groove. I-groove eyisihluthulelo engemuva komzimba we-tappet ingaholela uwoyela endaweni yokucindezela kawoyela ephansi ngaphezu kwe-plunger. Lapho i-cam iphenduka futhi umzimba we-tappet kanye ne-plunger iya phansi, uwoyela egumbini likawoyela elinomfutho ophezulu uyacindezelwa futhi umfutho kawoyela uyakhuphuka. Kanye nentwasahlobo yesinxephezelo, i-valve yebhola icindezelwa ngokuqinile esihlalweni esingezansi se-plunger. Lapho i-high-pressure oil room ihlukaniswa ne-low-pressure oil room. Ngenxa yokuthi uketshezi alukwazi ukucindezelwa, i-tappet yonke ihlehla njengesilinda, iphushe isiqu se-valve sivuleke. Ngalesi sikhathi, i-tappet annular oil groove iye yanyakaziswa ngembobo yamafutha e-oblique, futhi ukungena kwamafutha kuyayeka. Lapho i-tappet ifinyelela esikhungweni sayo esiphansi esifile futhi iqala ukuya phezulu, ngaphansi kwesenzo se-valve engenhla yesiphethu kanye nokucindezela okuphansi kwe-cam, igumbi likawoyela elinomfutho ophezulu livaliwe futhi i-valve yebhola ngeke ivuleke. I-tappet ye-hydraulic isengathathwa njenge-tappet eqinile ize iphakame. Kuze kube yilapho ikhamera isendingilizini yesisekelo futhi i-valve ivaliwe. Ngalesi sikhathi, uwoyela ocindezelayo endaweni eyinhloko kawoyela yekhanda le-cylinder ungena ekamelweni lamafutha okucindezela okuphansi kwe-tappet ngokusebenzisa imbobo yamafutha ethambekele. Ngesikhathi esifanayo, umfutho kawoyela egumbini likawoyela ophakeme wehla, futhi isiphethu sesinxephezelo siphusha i-plunger phezulu. Amafutha okucindezela avela ekamelweni lamafutha aphansi acindezela ukuvula i-valve yebhola ekamelweni likawoyela elinomfutho ophezulu, ukuze amakamelo amabili axhumeke futhi agcwaliswe ngamafutha. Ngalesi sikhathi, indawo engaphezulu ye-tappet isasondelene nekhamera. Lapho i-valve ishisa futhi inwetshiwe, i-plunger nesilinda esisebenza nge-hydraulic zinyakaza zihlobene komunye nomunye ohlangothini lwe-axial, futhi uwoyela osegumbini likawoyela elinomfutho ophezulu angampintsha egumbini likawoyela elinengcindezi ephansi ngegebe eliphakathi kwesilinda esine-hydraulic. kanye ne-plunger. Ngakho-ke, uma usebenzisa ama-tappets we-hydraulic, asikho isidingo sokugcina imvume ye-valve.

2. Umsebenzi we-push rod ukudlulisa i-thrust edluliswa kusukela ku-camshaft nge-tappet ukuya engalweni ye-rocker endleleni yokusabalalisa umoya we-valve engaphezulu kanye ne-camshaft engezansi. I-push rod iyingxenye eguquguqukayo kakhulu futhi izacile esitimeleni se-valve. Isakhiwo sawo esijwayelekile sihlanganisa izingxenye ezintathu: ikhanda lebhola le-concave eliphezulu, ikhanda eliphansi lebhola le-convex kanye nenduku engenalutho. Induku yokusunduza imvamisa yenziwa ngepayipi lensimbi elibandayo elidonsayo elingenamthungo, kanti amanye enziwe nge-duralumin. I-putter yensimbi eqinile ngokuvamile yenziwa ibe yonke ngokusekelwa okuyindilinga, bese iphathwa ngokushisa; iziphetho ezimbili ze-duralumin impahla eqinile ye-putter ifakwe izisekelo zensimbi, futhi iziphetho ezingenhla nezingezansi zihlanganiswe ne-shaft; Ikhanda lebhola langaphambili kanye I-shaft yenziwe ngokuphelele, futhi iziphetho ezimbili zamuva zihlanganiswe ne-shaft ngokushisela nokucindezela-fitting. Nakuba kunomehluko othile efomini lesakhiwo, izidingo zenduku yokusunduza ziyefana, okungukuthi, isisindo esilula nokuqina okuphezulu. Ngaphansi kwezimo ezijwayelekile, ukuze kuqinisekiswe ukulingana okulungile kwe-tappet, ingalo ye-rocker kanye ne-tappet, i-steel concave spherical joint is welded engxenyeni engenhla ye-push rod ukuze ifane nenhloko yebhola yesikulufu sokulungisa ingalo ye-rocker; Esokhethini lebhola le-concave.

3. Umsebenzi oyinhloko wengalo ye-rocker ukushintsha isiqondiso sokudlulisa amandla. Ingalo ye-rocker ilingana nesakhiwo se-lever, esidlulisela amandla enduku yokusunduza ekugcineni komsila wesiqu se-valve ukusunduza i-valve ukuze ivuleke; isilinganiso sobude bezingalo ezimbili (okuthiwa i-rocker arm ratio) sisetshenziselwa ukushintsha ukuphakama kwe-valve, ingalo ye-valve rocker Ngokuvamile, ikhiqizwa ngendlela yobude obungalingani. Ingalo eseceleni kwevalvu yinde ngo-30% kuya ku-50% kunengalo esehlangothini lwenduku yokusunduza, ukuze kutholakale ukuphakanyiswa kwevalvu enkulu.

Indawo yethu yokugcina impahla1

Pakisha bese uthumela

- I-Aerial Boom Lift

- Iloli lokulahla i-China

- Cold Recycler

- I-Cone Crusher Liner

- I-Container Side Lifter

- Ingxenye ye-Dadi Bulldozer

- Okunamathiselwe kwi-Forklift Sweeper

- Izingxenye ze-Hbxg Bulldozer

- Izingxenye ze-Howo Engine

- Hyundai Excavator Hydraulic Pump

- Izingxenye ze-Komatsu Bulldozer

- I-Komatsu Excavator Gear Shaft

- I-Komatsu Pc300-7 Excavator Hydraulic Pump

- Izingxenye zeBulldozer ze-Liugong

- Sany Concrete Pump Spare Parts

- Izingxenye ezisele ze-Sany Excavator

- Izingxenye Zenjini ye-Shacman

- Shantui Bulldozer Clutch Shaft

- I-Shantui Bulldozer Ixhuma Iphinikhodi ye-Shaft

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

- I-Shantui Bulldozer Lifting Cylinder Repair Kit

- Izingxenye ze-Shantui Bulldozer

- Shantui Bulldozer Reel Shaft

- I-Shantui Bulldozer Reverse Gear Shaft

- Izingxenye ze-Shantui Bulldozer Spare

- Shantui Bulldozer Winch Drive Shaft

- I-Shantui Dozer Bolt

- I-Shantui Dozer Front Idler

- Ikhithi yokulungisa i-Shantui Dozer Tilt Cylinder

- I-Shantui Sd16 Bevel Gear

- I-Shantui Sd16 Brake Lining

- I-Shantui Sd16 Door Assembly

- I-Shantui Sd16 O-Ring

- I-Shantui Sd16 Track Roller

- I-Shantui Sd22 Bearing Sleeve

- I-Shantui Sd22 Friction Disc

- I-Shantui Sd32 Track Roller

- Izingxenye ze-Sinotruk Engine

- Iloli Lokudonsa

- Izingxenye ze-Xcmg Bulldozer

- Izingxenye ze-Xcmg Bulldozer Spare

- I-Xcmg Hydraulic Lock

- Ukudluliselwa kwe-Xcmg

- Izingxenye ze-Yuchai Engine