Shantui Bulldozer ukulungisa

Izingxenye ze-Shantui Bulldozer

1. Ayikwazi ukuqala

Igandaganda alikwazanga ukuqala ngesikhathi kuvulwa i-hangar.

Ngemva kokuqeda isimo sokungabikho kukagesi, ukungabikho kukaphethiloli, okuxekethile noma okuvinjiwe kwamathangi kaphethiloli, njll., ekugcineni kwasolwa ukuthi i-PT fuel pump yayingasebenzi kahle. Hlola idivayisi yokulawula umoya nophethiloli. Ngemva kokuvula ipayipi lokungenisa nokusebenzisa i-compressor yomoya ukunikeza umoya epayipini lokungenisa, umshini ungaqala kahle. Uma ukunikezwa komoya kumisiwe, umshini uzocisha ngokushesha. Ngakho-ke, kunqunywa ukuthi idivayisi yokulawula umoya nophethiloli ayisebenzi kahle.

Khulula inathi yokulungisa yedivayisi yokulawula uphethiloli, vula idivayisi yokulawula uphethiloli ye-AFC ngokwewashi ngesikrufu sika-Allen, bese uqinisa intongomane yokulungisa. Uma umshini uqalwa kabusha, ungaqala ngokujwayelekile futhi iphutha liyanyamalala.

2. Ukwehluleka kohlelo lokuhlinzeka ngophethiloli

I-bulldozer idinga ukuxoshwa ngaphandle kwe-hangar ngesikhathi sokulungiswa kwesizini, kodwa ayikwazi ukuqhutshwa.

Hlola ithangi likaphethiloli, uphethiloli wanele; vula iswishi engxenyeni engezansi yethangi likaphethiloli, futhi izocisha ngokuzenzakalelayo ngemva komzuzu ongu-1 wokushayela; sebenzisa ipayipi lokungena lokuhlunga ukuze uxhume ngqo ithangi likaphethiloli epayipini likaphethiloli lephampu ye-PT. ; Qinisa isikulufu semanuwali se-valve ye-solenoid esike uwoyela endaweni evulekile, kodwa namanje asikwazi ukuqaliswa.

Lapho ufaka isihlungi kabusha, vula ukushintsha kwethangi likaphethiloli izikhathi ezi-3~5, futhi uthole inani elincane likaphethiloli eligeleza liphuma epayipini elingenisa isihlungi, kodwa uphethiloli uzophela ngemva kwesikhashana. Ngemva kokubhekwa ngokucophelela nokuqhathanisa okuphindaphindiwe, ekugcineni kwatholakala ukuthi inkinobho yethangi likaphethiloli ayizange ivulwe. Iswishi inesakhiwo esiyindilinga. Uma iphenduka i-90 °, i-oil circuit ixhunyiwe, futhi uma iphenduka i-90 °, i-oil circuit iyanqunywa. Iswishi ye-valve yebhola ayinaso isibambo futhi ayinaso isisetshenziswa esilinganiselwe, kodwa ikhanda lensimbi eliyisikwele liyavezwa. Umshayeli ube nephutha ukusebenzisa iswishi ye-valve yebhola njengokushintsha kwe-throttle. Ngemuva kokuphenduka oku-3 kuye ku-5, i-valve yebhola ibuyele endaweni evaliwe. Ngesikhathi sokujikeleza kwe-valve yebhola, nakuba inani elincane likaphethiloli lingena kumjikelezo wamafutha, lingaqhutshwa kuphela ngomzuzu ongu-1. Lapho uphethiloli osepayipini usuphelile, umshini uzocisha.

3. Ukuvuza kwamafutha ewintshini

Ngesikhathi kwakhiwa ugandaganda, ukuvuza kukawoyela kwenzeke ewindini lentambo yocingo. Ngemva kokukhipha zonke izintambo zocingo, kwatholakala ukuthi uwoyela we-hydraulic uvuza kumabhawodi asesihlalweni sewintshi, futhi lapho i-throttle inyuswa, ukuvuza kwakushesha, futhi cishe kwakungekho amafutha avuzayo lapho idling.

Ukuhlaziywa kokuqala kungase kubangelwe ama-bolts avulekile noma ama-gaskets awonakele, kodwa ngemva kokufaka ama-gaskets nokuqinisa ama-bolts, hlola umshini, iphutha lihlala. Ukuhlaziywa okwengeziwe komdwebo we-hydraulic schematic diagram kuphakamisa ukuthi isizathu singase sibe ukubuyiswa kahle kwamafutha kanye nokucindezela okukhulu emuva. Ngakho-ke, ipayipi elibuyisela uwoyela elisuka ewintshini liye kuvalvu yokulawula lashintshwa, okungukuthi, ipayipi elifushane lokubuyisela uwoyela lashiselwa engxenyeni engenhla yethangi likaphethiloli, esikhundleni salo kwafakwa ipayipi eliwugqinsi kunowoyela wokuqala. ipayipi lokubuyisela ukuze ukuphela kwepayipi lokubuyisela uwoyela kungaxhunywanga ku-valve yokulawula. Xhuma ngqo ipayipi elifushane lokubuyisela uwoyela ukuze unciphise ingcindezi yokubuyela emuva kawoyela. Zama umshini futhi iphutha liyanyamalala.

4. Injini yokushisa ayikwazi ukuhamba

Phakathi nokusetshenziswa, umshini obandayo waqala futhi i-bulldozing yayivamile, kodwa ngemva kwemizuzu engu-50 yomsebenzi, ugandaganda waba buthakathaka futhi waba buthakathaka njengoba izinga lokushisa likawoyela lalikhula kancane kancane, futhi kwakunzima ngisho nokuhamba ngaphansi komthwalo. Uma uyeka futhi uphumule amahora angu-2 ngalesi sikhathi, qala injini futhi ngemva kokwehla kwezinga lokushisa likawoyela, futhi isiqalo kanye ne-bulldozing kuzobuyela kokujwayelekile.

Ngesikhathi sokusebenza, i-throttle yenjini ayizange yehle futhi isivinini asizange sehle, okubonisa ukuthi ubuthakathaka be-bulldozer abuhlangene nenjini. Ukuhlaziywa kokuqala kukholelwa ukuthi imbangela ukuntuleka kwamafutha ku-converter ye-torque, ukuvinjelwa kwesifunda samafutha noma ukwehluleka kokudlulisela noma i-clutch yokuqondisa.

Hlola ukuthi isiguquli se-torque sijwayelekile; khulula isikulufu se-vent kusihlungi esihle sesivinini esiguquguqukayo, futhi kutholakala ukuthi kukhona amabhamuza kuwoyela okhishiwe, angakwazi ukuphelelwa isikhathi eside. Ukuhlaziywa kukholelwa ukuthi uma kukhona indawo lapho kungena khona umoya, kokubili okupholile kanye nokufudumala kufanele kukhishwe emoyeni, okwenza umshini usebenze ngokujwayelekile esimweni esibandayo, futhi kungaphetha ngokuthi umjikelezo kawoyela ophansi usesimweni esihle. . Ukungena komoya kwesekethe kawoyela enengcindezi ephezulu yenjini yokushisa kubangela ukuthi umshini wehluleke ukuhamba, okufanele kubangelwe ukuvaleka ngokweqile kwesekethe kawoyela enengcindezi ephansi.

5. I-bulldozing blade ayigijimi

Ngemva kokuqala injini, idivayisi yokulawula kanye ne-bulldozing blade ayizange iphendule. Hlola ithangi likawoyela we-hydraulic futhi uthole ukuthi ithangi likawoyela alinalutho. Ngokusho komshayeli ithangi likawoyela we-hydraulic ligcwaliswe ngaphambi kokuphuma emsebenzini ngayizolo. Ngakho-ke, i-pan kawoyela yenjini yahlolwa futhi izinga likawoyela latholakala likhuphuka. Khona-ke iphampu yamafutha esebenzayo yasuswa ukuze ihlolwe, futhi kwatholakala ukuthi uphawu lwamafutha olujikelezayo lwepompo yamafutha asebenzayo lonakalisiwe. Ithangi likawoyela we-hydraulic lisendaweni ephakeme, okuvumela uwoyela ukuthi ungene epanini likawoyela lenjini kadizili ngophawu lwawoyela ojikelezayo olimele ngobusuku obubodwa. Uma ubhekene nalesi simo, buyisela isivalo sikawoyela esisha kanye nowoyela wenjini, engeza uwoyela wehydraulic, bese ukhipha wonke umoya ohlelweni lwe-hydraulic ukuze ibhuldoza ikwazi ukusebenza ngendlela evamile.

6. Ayikwazi ukuqala injini ye-diesel

Isici sokuhlunga sesihlungi sikaphethiloli senjini sivinjiwe noma ulayini wamafutha uvinjelwe. Kulesi simo, isici sokuhlunga uphethiloli kufanele sihlanzwe noma sifakwe esisha, futhi umugqa wamafutha kufanele uhlanzwe ngesikhathi esifanayo.

Kukhona uphethiloli kusilinda. Hlola izinga likaphethiloli ethangini likadizili. Uma uphethiloli unganele, engeza uphethiloli, hlanza umlomo womjovo kaphethiloli noma ufake omusha.

7. U-gearbox awukwazi ukusebenza ngegiya elithile

I-seal ring yomugqa wamapiston ka-gearbox yonakele, futhi ubuso bokugcina bomugqa wamagiya eplanethi bulimele. Uma lokhu kuyiqiniso, shintsha iphedi yokuvala noma iringi ufake entsha.

I-gearbox lever system ayilungiswanga kahle noma iyaxega. Uma ubhekene nesimo esinjalo, kubalulekile ukulungisa kabusha uhlelo lwe-lever gearbox.

8. Vimbela umgadli wegandaganda ukuthi angagqoki

Ukushuba kweketango kuzothinta ukushelela, ukucindezela kanye nokungqubuzana phakathi kwezingxenye zomshini wokugijima wegandaganda. Kuphela uma ukushuba kweketango sekumaphakathi lapho ukuguga kwendlela yokuhamba kungancishiswa futhi ukuxega kweketango kungagwenywa. Ngakho-ke, ukuqina kweketango kubaluleke kakhulu. Ukungezwani kweketango kukhulu kakhulu, okwandisa ingcindezi nokungqubuzana phakathi kwezingxenye ezihambayo ezihambayo zomshini wokuhamba, futhi ukungqubuzana kuyanda, umsindo okhiqizwa yilo ubukhali futhi unzima, okwandisa ukuguga. Ikakhulukazi iketango elihlanganisiwe nesondo, indawo ehlanganisiwe ayibushelelezi, okwenza ukuthi indawo yokuxhumana phakathi kwezingxenye iyancipha kakhulu, ukuze ukugqoka kukhuphuke, okubangela ungqimba we-welding we-roller kanye ne-chain link. . Izenzakalo ezibalwe ngenhla nazo zingabangela izingxenye ukuthi zishise ngenxa yokugqoka, futhi ekugcineni ziholele ekuhlulekeni ngaphambi kwesikhathi kwezimpawu zengxenye ngayinye kanye nokulimala ezingxenyeni.

Indawo yethu yokugcina impahla1

Pakisha bese uthumela

- I-Aerial Boom Lift

- Iloli lokulahla i-China

- Cold Recycler

- I-Cone Crusher Liner

- Isitsha Side Lifter

- Ingxenye ye-Dadi Bulldozer

- Okunamathiselwe kwi-Forklift Sweeper

- Izingxenye ze-Hbxg Bulldozer

- Izingxenye ze-Howo Engine

- I-Hyundai Excavator Hydraulic Pump

- Izingxenye ze-Komatsu Bulldozer

- I-Komatsu Excavator Gear Shaft

- I-Komatsu Pc300-7 Excavator Hydraulic Pump

- Izingxenye zeBulldozer ze-Liugong

- Sany Concrete Pump Spare Parts

- Izingxenye ezisele ze-Sany Excavator

- Izingxenye Zenjini ye-Shacman

- Shantui Bulldozer Clutch Shaft

- I-Shantui Bulldozer Ixhuma i-Shaft Pin

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

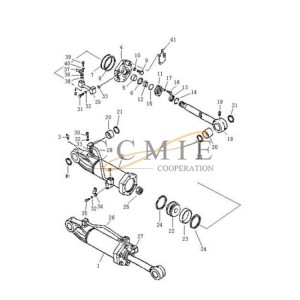

- I-Shantui Bulldozer Lifting Cylinder Repair Kit

- Izingxenye ze-Shantui Bulldozer

- Shantui Bulldozer Reel Shaft

- I-Shantui Bulldozer Reverse Gear Shaft

- Izingxenye ze-Shantui Bulldozer Spare

- Shantui Bulldozer Winch Drive Shaft

- I-Shantui Dozer Bolt

- I-Shantui Dozer Front Idler

- Ikhithi yokulungisa i-Shantui Dozer Tilt Cylinder

- I-Shantui Sd16 Bevel Gear

- I-Shantui Sd16 Brake Lining

- I-Shantui Sd16 Door Assembly

- I-Shantui Sd16 O-Ring

- I-Shantui Sd16 Track Roller

- I-Shantui Sd22 Bearing Sleeve

- I-Shantui Sd22 Friction Disc

- I-Shantui Sd32 Track Roller

- Izingxenye ze-Sinotruk Engine

- Iloli Lokudonsa

- Izingxenye ze-Xcmg Bulldozer

- Izingxenye ze-Xcmg Bulldozer Spare

- I-Xcmg Hydraulic Lock

- Ukudluliselwa kwe-Xcmg

- Izingxenye ze-Yuchai Engine