Wheel rim XCMG Liugong motor grader izingxenye ezisele

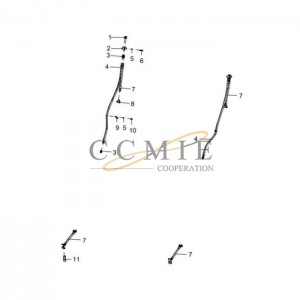

Isondo lesondo

Ngenxa yokuthi kunezinhlobo eziningi zezingxenye ezisele, asikwazi ukuziveza zonke kuwebhusayithi. Sicela uzizwe ukhululekile ukusithinta ukuze uthole ezithile.

Inzuzo

1. Sikuhlinzeka ngemikhiqizo yoqobo neyemakethe yangemuva

2. Kusukela kumkhiqizi kuya ekhasimendeni ngokuqondile, ukonga izindleko zakho

3. Isitokwe esizinzile sezingxenye ezijwayelekile

4. Ngesikhathi Sokulethwa Kwesikhathi, esinezindleko zokuncintisana zokuthumela

5. Professional futhi ngesikhathi ngemva kwenkonzo

Ukupakisha

Amabhokisi e-Carton, noma ngokusho kwesicelo samakhasimende.

incazelo

Ekusebenzeni kwe-motor grader, izindaba ezidinga ukunakwa ziyingxenye yomklamo wokuhlanganiswa kwerimu

1. Umsebenzisi wegreda kufanele abe nolwazi namakhono ekusebenzeni kwegandaganda noma isilayishi.

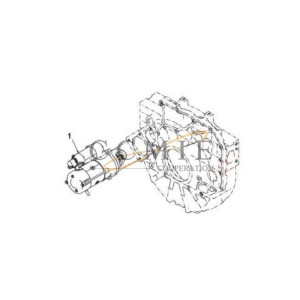

2. Lapho usebenzisa umshini wokulinganisa umshini, qaphela ukuthi ingabe ukhona yini umsindo ongajwayelekile engxenyeni ngayinye yenjini kanye ne-chassis, nokuthi ingabe likhona yini iphunga elibangelwa ukushiswa kwezingxenye ezihixisayo.

3. Ngokwezinguquko zonyaka kanye nezinguquko zokushisa kwemvelo, uwoyela we-hydraulic ofanele, uwoyela wokugcoba (amafutha) kanye nophethiloli kufanele kukhethwe ngokuhambisana nebhukwana lemiyalo. Amafutha asetshenzisiwe ngeke ashintshwe ngaphandle kwemvume esemthethweni yomnyango wokuphatha.

4. Impahla yokufaka uphethiloli kufanele ihlungwe ngokuqinile ukuze kuqinisekiswe ukuthi isiqukathi sokuthela uphethiloli, indawo yokufaka uphethiloli kanye nenqubo yokufaka uphethiloli akungcolisiwe.

5. Imithethonqubo mayelana nokusetshenziswa kwezinto ezisebenza ngogesi.

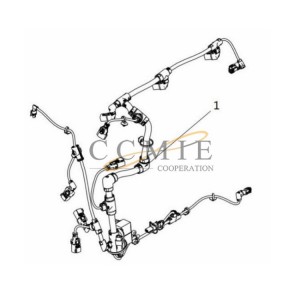

6. Uma uhlola isifunda, uma uhlangabezana nezingxenye ezinamafutha futhi ezibamba kalula, sebenzisa isibani sokuhlola noma imitha kagesi ukuhlola. Cha 7. Ukufakwa kocingo kufanele kube kuhle, amalunga kufanele aqine futhi aqine, ahlanganiswe ngetheyiphu noma ambozwe ngamapayipi epulasitiki ukuvimbela ukuvuza komhlaba.

8. Imithethonqubo mayelana nokusetshenziswa kwamabhethri

9. Ungenzi ukushisela noma ukusika igesi eduze kwepayipi likawoyela ocindezelayo wegreda yemoto noma ezinye izinto ezivuthayo. Lapho kudingeka ukushisela, kufanele uqale ucime injini, unqamule inkinobho enkulu yebhethri, noma unqamule intambo yaphansi yebhethri ekhanda lenqwaba, ukuze ugweme imiphumela emibi yesifunda esifushane samandla kagesi. ngesikhathi somsebenzi. Intambo yomhlabathi ye-welder kagesi kufanele ixhunywe ku-workpiece ukuze ihlanganiswe, futhi isondele ngangokunokwenzeka engxenyeni ye-welding.

10. Vuthela isondo ngomfutho oshiwo umenzi wamasondo. Lapho umoya uphefumula, kufanele kusetshenziswe ishubhu yerabha ende ene-chuck ezivalelayo, futhi umuntu kufanele ame ngemuva kwesondo.

11. Ngaphambi kokukhipha into eshumekwe ethayini noma ukuqaqa isondo lesondo, defa isondo. 12. Akuvunyelwe ngokuphelele ukuxuba izingxenye ze-rim ezivela kubakhiqizi abahlukene, futhi akuvunyelwe ukusebenzisa izinsimbi ezilimele noma ezigugile. Irimu kufanele ifakwe ngendlela efanele.

13. Ukuvikela ukuthi isondo lingaqhumi ngenxa yokushisa okukhulu. Uma kwenzeka lesi simo, kufanele uqaphele ukude futhi ulinde amasondo ukuthi aphole ngaphambi kokusondela ku-motor grader. Uma isondo liqhuma kungazelelwe futhi livuze phakathi nokushayela, ngemva kokuma, umshayeli angahamba ngemva kokuba isondo selipholile.

14. Ukugcinwa nokufakwa esikhundleni samathayi namarimu kufanele kwenziwe ngabasebenzi abakhethekile abanamathuluzi akhethekile kanye nemishini. 15. Lapho uhlangabezana nemisebenzi yokuqhuma kokwakhiwa, umshini wokulinganisa umshini kufanele ukhishwe ngokushesha endaweni eyingozi futhi upakwe endaweni esezingeni elingenazo izingozi zokuphepha ukuze kuqinisekiswe ukubhuleka okuthembekile. Ungashayeli i-motor grader endaweni eyingozi lapho i-alamu ingacishiwe.

16. Uma udlula ibhuloho, naka umthamo wokuthwala uphawu lwebhuloho. Ngamabhuloho angenazo izimpawu, kufanele uxhumane neminyango efanele ukuze uqinisekise ukuthi angakwazi ukuthwala isisindo sendiza ngaphambi kokuba idlule. Lapho uwela ibhuloho, sebenzisa isivinini sokuqala.

Indawo yethu yokugcina impahla1

Pakisha bese uthumela

- I-Aerial Boom Lift

- Iloli lokulahla i-China

- Cold Recycler

- I-Cone Crusher Liner

- I-Container Side Lifter

- Ingxenye ye-Dadi Bulldozer

- Okunamathiselwe kwi-Forklift Sweeper

- Izingxenye ze-Hbxg Bulldozer

- Izingxenye ze-Howo Engine

- Hyundai Excavator Hydraulic Pump

- Izingxenye ze-Komatsu Bulldozer

- I-Komatsu Excavator Gear Shaft

- I-Komatsu Pc300-7 Excavator Hydraulic Pump

- Izingxenye zeBulldozer ze-Liugong

- Sany Concrete Pump Spare Parts

- Izingxenye ezisele ze-Sany Excavator

- Izingxenye Zenjini ye-Shacman

- Shantui Bulldozer Clutch Shaft

- I-Shantui Bulldozer Ixhuma Iphinikhodi ye-Shaft

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

- I-Shantui Bulldozer Lifting Cylinder Repair Kit

- Izingxenye ze-Shantui Bulldozer

- Shantui Bulldozer Reel Shaft

- I-Shantui Bulldozer Reverse Gear Shaft

- Izingxenye ze-Shantui Bulldozer Spare

- Shantui Bulldozer Winch Drive Shaft

- I-Shantui Dozer Bolt

- I-Shantui Dozer Front Idler

- Ikhithi yokulungisa i-Shantui Dozer Tilt Cylinder

- I-Shantui Sd16 Bevel Gear

- I-Shantui Sd16 Brake Lining

- I-Shantui Sd16 Door Assembly

- I-Shantui Sd16 O-Ring

- I-Shantui Sd16 Track Roller

- I-Shantui Sd22 Bearing Sleeve

- I-Shantui Sd22 Friction Disc

- I-Shantui Sd32 Track Roller

- Izingxenye ze-Sinotruk Engine

- Iloli Lokudonsa

- Izingxenye ze-Xcmg Bulldozer

- Izingxenye ze-Xcmg Bulldozer Spare

- I-Xcmg Hydraulic Lock

- Ukudluliselwa kwe-Xcmg

- Izingxenye ze-Yuchai Engine